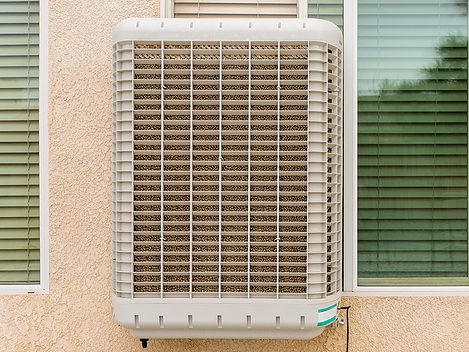

Evaporative coolers, also known as a swamp cooler, are a good option if you’re looking for a means to cool down in the summer.

Due to the high humidity, they aren’t as effective. You may increase their cooling capacity by ensuring they are working correctly and regularly cleaned.

The evaporative cooler media is an essential part of any evaporative cooler.

While allowing the cooling media to absorb water, the cooling pads are also intended to allow air to travel through. To cool the air, passing it through a water-soaked cooling medium is necessary.

Due to impurities in the water and high pH levels, the cooling media deteriorates over time (typically 6-12 months). This is due to the effects of physical degradation and dust, pollen, and other wind-borne material.

Damage to your evaporative cooler’s evaporative cooler media reduces its efficiency, and it is no longer able to work as well as previously.

Regular evaporative cooler maintenance should include checking the following items.

Forewarned about Media Softening – Your Swamp Cooler Pads have Gone Bad

Evaporative coolers are available in various shapes and sizes, each with a specific application. Scope and application affect the evaporative media used in each type of device.

Small, portable evaporative coolers are an option for households with no more than 300 square feet of cooling needs. On the other hand, evaporative cooling systems can be found in much larger homes with water lines running through them.

There are multiple layers and layers of cooling pads on industrial evaporative coolers that are utilized in manufacturing, agriculture, and perishable food storage.

The appearance of a softening media is a solid sign that your evaporative pads need to be replaced. Both natural and synthetic fibers can absorb water. The material softens and degrades as it comes into contact with the water’s various chemicals and minerals.

The drooping and stretching of the cloth are evidence of this.

The synthetic fiber structures are subject to chemical degradation and physical damage when things in the air are blasted into the material, notwithstanding the claims of makers of high-efficiency cooling materials.

When working in a harsh climate, you’ll need to replace the cooling medium more frequently.

New cooling media will better chill ambient air, but the evaporative cooler’s power consumption will be reduced, too.

It’s time to look at the causes and effects of static pressure

Increased Static Pressure and Its Effects

Static pressure rises due to the cooling medium’s increased resistance to airflow.

If your swamp cooler, commonly known in the southern regions, is to function correctly, it must have a continual flow of air through the cooling pads.

Air is pushed through the cooling medium due to the enormous pressure gradient created by large industrial fans. Heat is transferred from the air molecules to the fabric’s water molecules, causing the water to evaporate and removing heat from the atmosphere.

As the amount of air being cooled decreases, the amount of air traveling through the evaporative cooling system increases. As a result, any reduction in the volume of air flowing through the system may lessen its ability to cool effectively.

Evaporative cooler media become clogged when airborne particles such as dust, pollen, leaves, and branches find their way into it. In addition to slowing down airflow and reducing the amount of heat exchanged with water, this increases static pressure, which can have other detrimental effects.

The lifespan of the cooling medium can be extended significantly by performing routine checks on the cooling pads. To keep the material in good condition, keep it free of twigs, leaves, plastic, and dust, and fix any tears.

To counterbalance the increased resistance to airflow through the cooling pads, there will be increased wear and tear on belts and pulleys and the motor driving the fans.

With less cooling, you’ll also have more significant maintenance expenditures and a shorter lifespan of the system’s components.

If the static pressure in your system rises above a predefined level, a brief cost-benefit analysis will reveal that changing the evaporative media is prudent.

What causes the evaporative cooling system to lose its ability to cool?

Observe a Decrease in the Temperature of the Water.

Checking your system’s temperature in real-time is the most straightforward method. Temperature sensors coupled to a sender unit generate a meaningful graph and rapidly reveal a declining efficiency trend.

However, even the most efficient evaporative coolers can only drop the ambient temperature by roughly 15-40°F (0.5-1.25°C)…

An increase in relative humidity significantly reduces this cooling capacity. Because of this, evaporative coolers should not be used in hot, humid conditions.

However, a decrease in wind speed results in a loss of cooling.

Reduced Wind Speed also has an impact on the cooling process

Temperature decrease is proportional to the airflow rate across the evaporative media.

The efficiency of the cooling pads will be reduced by anything that impedes airflow. When evaporative media or ducting has tears or leaks, the airflow and cooling will be affected.

Regular inspection of the evaporative media for deterioration is necessary to maintain the system’s evaporative efficiency. If the damage is minor, most evaporative pads can be restored. As time passes, however, the material will degrade further, decreasing the system’s wind speed.

Maintaining Your Evaporative Cooler Is Essential

Make sure to turn off your cooling system when it isn’t in use. The water supply is included in this. Before putting away portable systems, ensure that all the pipes and storage tanks are entirely drained, and the filters are well cleaned.

The mineral buildup in the evaporative cooler media can be prevented or slowed down by analyzing your water and using treatment tablets where required.

Contact Day & Night Plumbing in Albuquerque, NM, and the surrounding region for help installing evaporative coolers. Evaporative cooling systems are manufactured and installed by a team of experts with more than 30 years of expertise in the industry. In addition, they may provide you with any necessary spare parts or accessories.